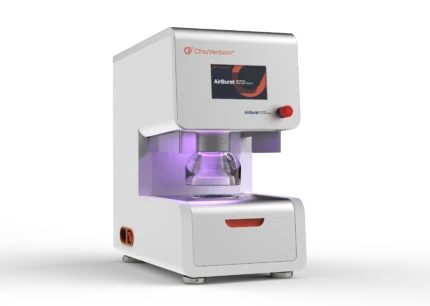

CoolMax Cool Feeling Tester

Key Features

-

Instant Cooling Performance Testing

Measures heat dissipation and cooling effect of textiles for sportswear, outdoor gear, home furnishings, automotive interiors, and functional fabrics. -

Fast & Accurate Q-max Results

Delivers contact coolness coefficient (Q-max) values in seconds for R&D, production, and QC. -

Smart IoT Integration

Remote control via mobile app: preheat detection board, schedule tests, and monitor deviations. -

Third-Party Validated Reliability

Results align with authoritative lab tests for trusted performance benchmarking.

Technical Specifications

| Parameter | Value |

|---|---|

| Power Supply | 220V, 50/60Hz |

| Weight | 35 kg |

| Dimensions (W×D×H) | 540 × 468 × 345 mm |

| Heat Detection Plate Temp. | 35±0.5°C (adjustable: 20–40°C) |

| Response Time | <0.2 seconds |

| Test Duration | 1–600 s (adjustable) |

| Sample Area | 200 × 200 mm |

| Cold Plate 1 (Foam) | 210 × 210 mm (polyester foam) |

| Cold Plate 2 (Copper) | 180 × 180 mm; temp: 25°C (adjustable to <10°C) |

| Temp. Display Resolution | 0.01°C |

| Testing Method | Fully automated (no manual plate movement) |

Testing Principle

-

Heat Transfer Measurement:

-

A preheated detection plate (35°C) contacts the sample.

-

-

Q-max Calculation:

-

Records temperature drop over time.

-

Calculates max heat flow density: Q-max [J/(cm²·s)].

-

-

Performance Rating:

-

Higher Q-max = Stronger cooling effect (e.g., skin-contact coolness).

-

Compliance Standards

-

JIS L1927

-

FTTS-FA-019

-

GB/T 35263-2017

-

CNS 15687-2013

Smart Capabilities

-

Remote Control (SmarTexLab App):

-

Preheat detection board, start/stop tests, schedule operations.

-

-

Real-Time Monitoring:

-

Tracks ambient temperature deviations via built-in sensors.

-

-

Data Traceability:

-

Logs test parameters, results, and environmental conditions.

-