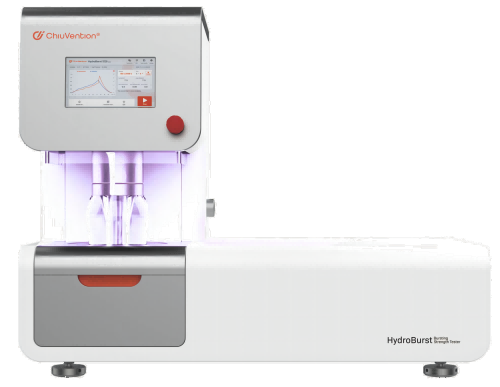

HydroBurst Bursting Strength Tester

Key Features

-

Hydraulic Expansion Testing

Measures expansion force/degree and bursting resistance of knitted/woven/nonwoven fabrics, laminated materials, paper, and elastic textiles under multidirectional force. -

AI-Controlled Precision

One pre-test calibrates bursting speed to meet 20s standard requirements (ISO/GB/ASTM). -

Smart Test Cup Recognition

Auto-detects cup size and switches parameters without manual input. -

High-Accuracy Sensors

0.2-grade pressure sensors with extended lifespan (laser displacement tech prevents damage).

Technical Specifications

| Parameter | Value |

|---|---|

| Power Supply | 220/110V, 50/60Hz |

| Weight | 130 kg |

| Dimensions (L×W×H) | 830 × 500 × 660 mm |

| Model | CV142 HydroBurst |

| Accuracy | ≤10cm² cup: ±1% (0–10 MPa) 50cm² cup: ±1% (0–3 MPa) 100cm² cup: ±1% (0–1 MPa) |

| Hydraulic Medium | Glycerin (7.HY.004, 500 ml) |

| Max. Expansion Height | 65±1 mm (70±1 mm with 50cm² cup) |

| Operating Environment | 20°C±5°C, 50–70% humidity |

Test Fixtures & Accessories

| Component | Model Code | Specifications |

|---|---|---|

| Test Cup 1 (Std.) | 2.Z.CV 142.01 | 7.3cm² (Ø30.5mm±0.2mm) |

| Lower Fixture 1 (Std.) | 2.Z.CV 142.11 | 7.3cm² (Ø30.5mm±0.2mm) |

| Test Cup 5 (Std.) | 2.Z.CV 142.05 | 50cm² (Ø79.8mm±0.2mm) |

| Lower Fixture 5 (Std.) | 2.Z.CV 142.15 | 50cm² (Ø79.8mm±0.2mm) |

| Test Cup 2 (Opt.) | 2.Z.CV 142.02 | 7.55cm² (Ø31mm±0.2mm) |

| Lower Fixture 2 (Opt.) | 2.Z.CV 142.12 | 7.55cm² (Ø31mm±0.2mm) |

| Test Cup 4 (Opt.) | 2.Z.CV 142.04 | 10cm² (Ø35.7mm±0.2mm) |

| Lower Fixture 4 (Opt.) | 2.Z.CV 142.14 | 10cm² (Ø35.7mm±0.2mm) |

| Test Cup 6 (Opt.) | 2.Z.CV 142.06 | 100cm² (Ø113mm±0.2mm) |

| Lower Fixture 6 (Opt.) | 2.Z.CV 142.16 | 100cm² (Ø113mm±0.2mm) |

| Test Diaphragm (Opt.) | 4.M.020 | Ø148mm × 1.6mm (10pcs/box) |

Compliance Standards

| Standard | Fixture Area |

|---|---|

| FZ/T01030-2016 Method B | 7.3cm² (Ø30.5mm) |

| GB/T7742.1-2005 | 50cm² (Ø79.8mm) |

| ISO13938-1-2019 | 10cm² (Ø35.7mm) |

| ASTM D3786/3786M-18 | 7.55cm² (Ø31±0.75mm) |

| EN 12332-2-2002 | 100cm² (Ø113±1mm) |

Smart Capabilities

-

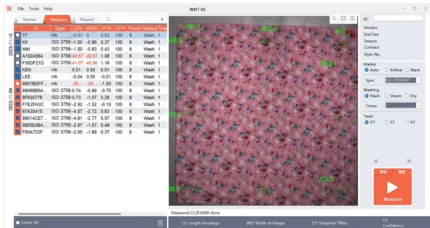

IoT Integration (SmarTexLab APP):

-

Direct ERP/LIMS connectivity for test orders and digital reports.

-

QR code scanning for sample tracking.

-

Remote monitoring, test modification, and completion alerts.

-

-

Automated Data Logging:

-

Records test process, results, temperature, humidity.

-

-

Maintenance Support:

-

OTA updates, calibration reminders, consumable replacement alerts.

-

Live customer service chat.

-

Key Innovations

-

Precision Screw Drive + AI Algorithm:

-

Ensures bursting speed compliance with ISO/GB/ASTM 20s standard.

-

-

Laser Displacement Sensors:

-

Replaces error-prone rod systems; prevents bending/damage.

-

-

Auto-Calibration:

-

Maintains ±1% accuracy across all test cup sizes.

-