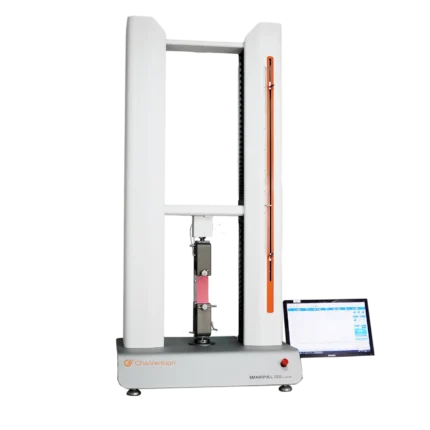

BeanSnag Bean Bag Snag Tester

Key Features

-

Realistic Simulation

Tumbles fabric pillows with weighted bean bags in cylinders with needle bars to replicate real snagging scenarios. -

Wide Fabric Compatibility

Tests knitted/woven fabrics, synthetic filaments, and textured yarns (not recommended for mesh fabrics). -

Durable & Quiet

High-quality aluminum alloy construction with surface hardening; operational noise <50 dB. -

User-Centric Design

Built-in observation drum for safety, ergonomic interface, and power-fail data protection.

Technical Specifications

| Parameter | Value |

|---|---|

| Power Supply | 220/110V, 50/60Hz |

| Weight | 50 kg |

| Dimensions (L×W×H) | 590 × 290 × 440 mm |

| Testing Stations | 2 |

| Testing Speed | 20 rpm |

| Test Cycles | 0–99,999,999 (adjustable) |

| Cylinder Size | Ø200 mm × 145 mm |

| Inner Drum Size | Ø180 mm × 127 mm |

| Needle Bars | 8 bars × 9 pins each |

| Standard Accessories | Needle bars with pins, 215×115 mm sampling board |

Testing Principle

-

Sample Preparation:

-

Fabric sample sewn into a bag containing a steel-ball-filled “bean bag.”

-

-

Testing Process:

-

Secured pillow tumbles 360° inside a needle-lined cylinder (100 rotations typical).

-

-

Result Assessment:

-

Post-test evaluation of snag resistance (e.g., pilling rating).

-

Key Benefits

-

Reliability:

Microprocessor-controlled process ensures stable, repeatable results. -

Longevity:

Scratch-resistant hardened surface extends service life. -

Safety:

Enclosed drum design protects operators during testing.