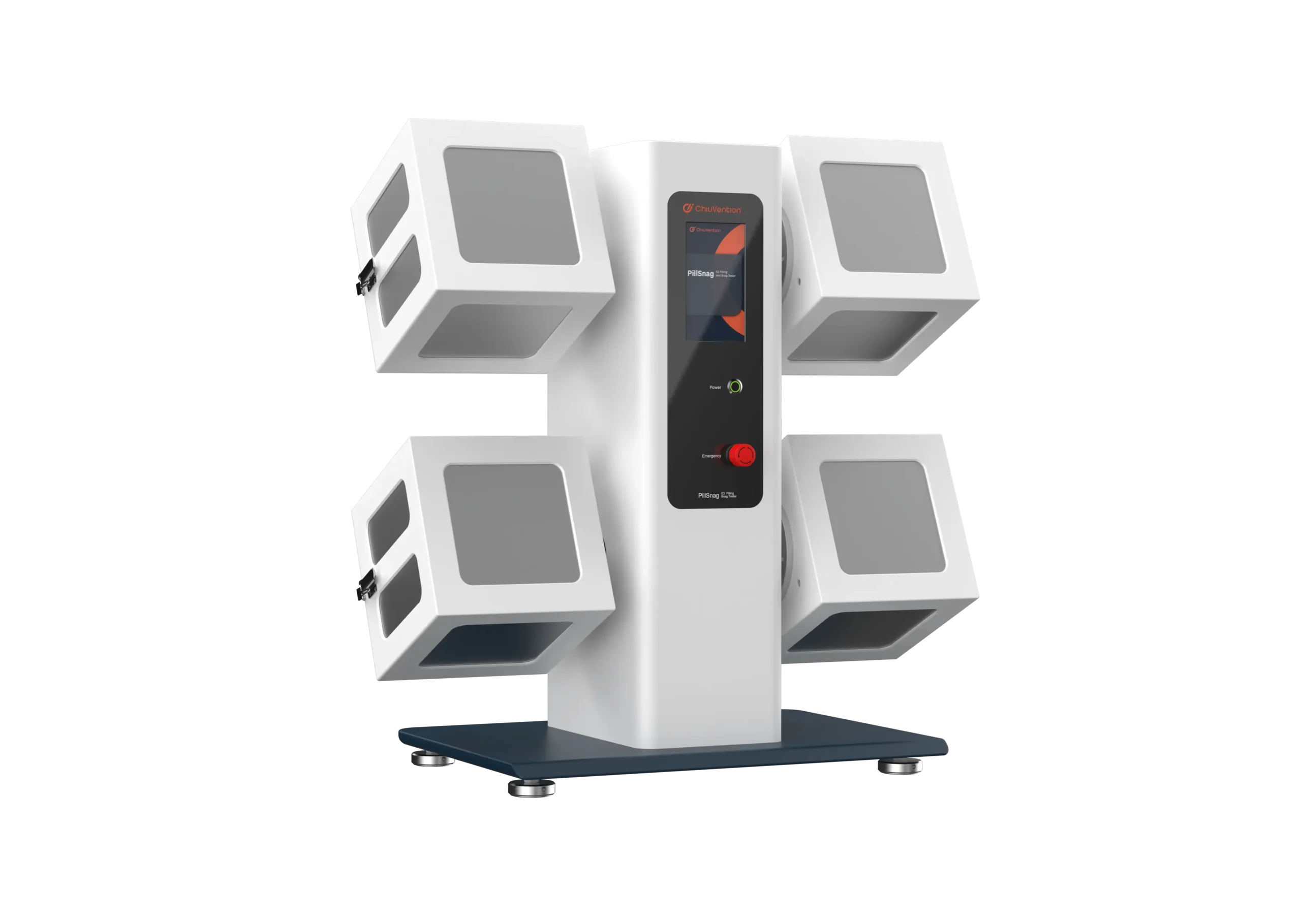

PillSnag Pilling and Snagging Tester

Overview

-

Evaluates pilling/hooking properties of textiles through simulated wear.

-

Flexible configurations: 2 or 4 stations, round/octagonal boxes (EU brands), EU/JP hook-and-loop boxes.

-

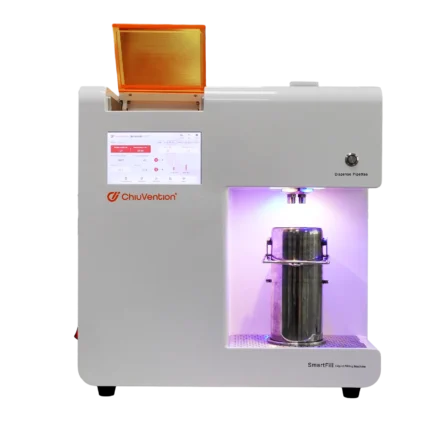

IoT-enabled for ERP/LIMS integration via SmarTexLab APP.

Testing Principle

-

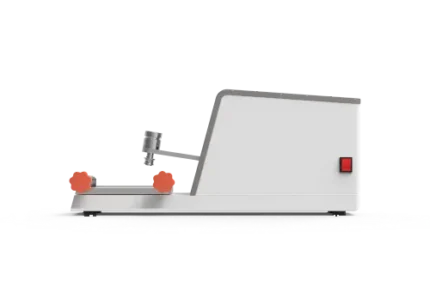

Sample Mounting:

-

Textile wrapped around polyurethane tube.

-

-

Abrasion Simulation:

-

Tube rotates in cork-lined box with abrasive/hooking nails.

-

-

Result Assessment:

-

Post-test comparison to standardized samples (pilling/hooking grades).

-

Technical Specifications

| Parameter | Value |

|---|---|

| Power Supply | 220/110V, 50/60Hz |

| Weight | 100 kg |

| Dimensions (D×W×H) | 470 × 860 × 900 mm |

| Chamber Size | 235×235×235 mm (excl. cork lining) |

| Rotation Speed | 30–70 rpm (adjustable) |

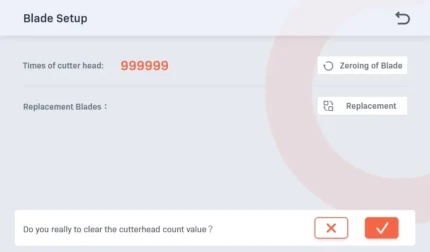

| Rotation Count | 2–999,999 cycles (settable) |

| Custom Stations | 2 or 4 chambers |

| Rotation Function | Forward/reverse |

Accessories

| Component | Standard | Optional |

|---|---|---|

| Sampling Board | 1 pc (125×125 mm) | 1 pc (114×114 mm) |

| Polyurethane Tube | 16 pcs (Ø31.5×140 mm) | 4 pcs (Ø31.5×140 mm) |

| Cork Liner | 24 pcs | 6 pcs/set |

| Mounting Jig | – | 1 pc |

| Pilling Standard Photos | – | 20 pcs (4 sets × 5) |

Compliance Standards

| Standard | Type |

|---|---|

| ISO 12945-1 | Standard |

| GB/T 4802.3 | Standard |

| NEXT TM19 | Standard |

| BS 5811 | Standard |

| BS 8479 | Optional |

| JIS L1058 Method D-2 | Optional |

Smart Capabilities

-

IoT Integration (SmarTexLab APP):

-

Remote test control, QR code sample scanning, real-time monitoring.

-

Digital records (process, results, temperature, humidity).

-

ERP/LIMS-compatible reports.

-

-

Automated Workflow:

-

OTA updates, calibration reminders, consumable replacement alerts.

-

Direct customer support chat.

-

Testing Modes

-

EU Octagonal Box (BS 8479):

Simulates European garment wear conditions. -

Multi-Standard Compatibility:

Configurable for ISO, GB, JIS, and brand-specific protocols.